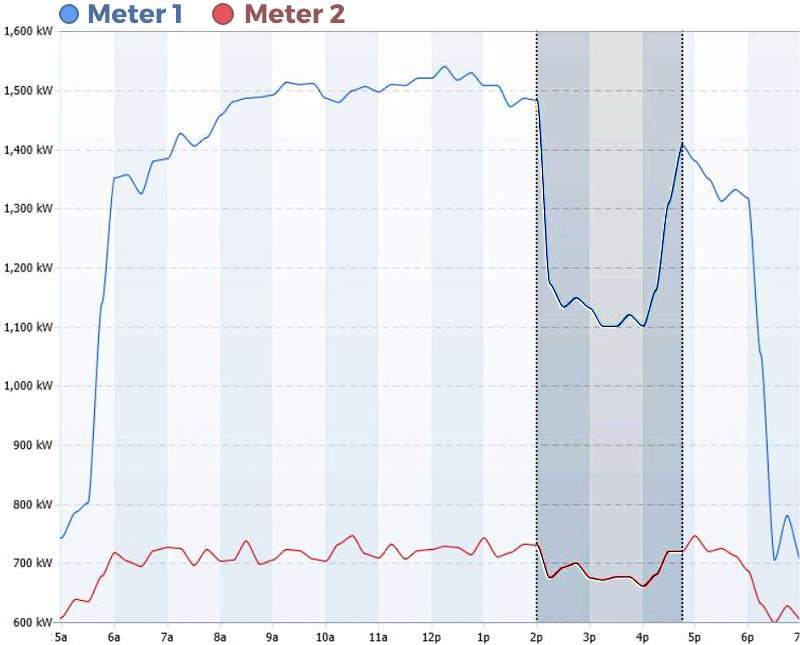

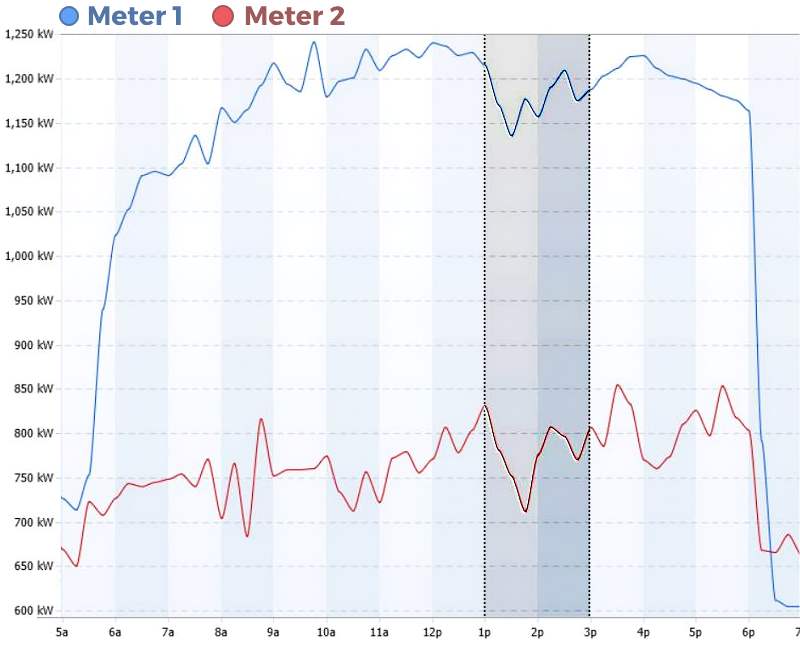

The objective of this case study was to determine what The Tri-M Group could do to reduce consumption when the reliability of the electric grid is in jeopardy as requested by the supplier. In order to test the demand reduction strategies, the equipment commands and space temperature setpoints were manipulated during peak demand conditions using the building automation system. Peak demand conditions include extreme hot and extreme cold weather. The system logged historical data for space temperature, space humidity, space CO2, and two main electric meters during the test periods. The historical data was then analyzed using Tri-M Analytics.